Vallorbs Material Rack Kaizen Event

Vallorb’s lawww Kaizen event occurred last week from 11-10-14 to 11-13-14. The focus of our event was to sort the materials we currently have in to types of material, like Zirconium, Stainless Steel and Brass, so that it is easier to find material and visually more appealing to visitors and external auditors who visit our location. But as most Kaizen events tend to do, we quickly shifted our focus as we discovered a way to turn the sorting of a material rack in to hundreds of extra hours of production capacity for our CNC machines.

We started by removing all of the material we had on our rack that was out dated, did not have proper certification or was extra from obsolete product. And it was while we were removing the material that revealed the silver lining in our Kaizen event. Every so often, while we were removing material, we had to stop to allow operators the time to get material. We began to wonder if there was a way to eliminate the operators from having to leave their machine to come and get stock.

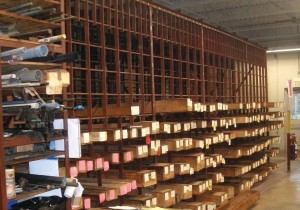

After meeting on this subject with the team, we created a procedure that allows our Materials Receiver to point and mark each bar of material as it is received. Once it is received and placed in a location, the material will be delivered to the machine on a schedule, based on the part being produced. This will allow the machine operator to stay at their machine and continue to run production. We later found out that each operator spent between 10 and 20 minutes a day signing out material, pointing the material so that we could use it in the bar feeders for the CNC machine and marking the material so that we could tell when the material was about to run out. It does not sound like a lot of time, but when you add up the ten minutes for each of the 1 operators covering 2 shift and extrapolate out the numbers, it was reducing our production capacity by over 500 hours a year. We were also able to achieve the original plan of cleaning up the material rack and segregating the material by type. Although we are not 100% complete, you can see the drastic change our material rack has gone through, as we have remove over 50% of the material that was originally stored on the rack.

Special thanks to Barry Gochnauer Sr., Louie Laramie, George Blizzard, Ken Rinier, Todd Thomas and Todd Suessmuth for their work on achieving these results.